Technology

High in power, large in capacity & completely green

High in power, large in capacity & completely green

We provide green energy anywhere, anytime. The Watermeln hydrogen generator solution consists of two components: the WM-200 unit and external hydrogen tanks.

The Watermeln 200 is an innovative genset that works on the basis of chemical reactions, meaning no combustion takes place. The fuel cell converts hydrogen into electricity and heat through a chemical process, while the battery provides peak power delivery and ensures an optimal balance between supply and demand.

Our hydrogen tanks store hydrogen gas at high pressure, allowing a much larger volume of gas to fit in one cubic metre. The hydrogen is produced by splitting water into oxygen and hydrogen using electricity sourced from regional renewable energy sources such as wind or solar.

This way, we not only achieve emission-free power on-site but also ensure the entire chain is sustainable and emission-free.

The mobile hydrogen generator based on fuel cell and battery technology. The unit can operate in 3 operational modes: stand-alone off-grid, grid-connected, or with an additional battery for peak load.

Each Watermeln unit comes standard with one or multiple hydrogen tanks.

Hydrogen gas (H2) is a promising and environmentally friendly energy carrier with various applications, including vehicle fuel, electricity storage, and industrial processes. One of the most commonly used methods to produce hydrogen is electrolysis, followed by high-pressure storage. Let's break it down step by step:

These sources are not depleted, cause minimal pollution, and reduce reliance on fossil fuels. By producing hydrogen from these sustainable sources, we increase the capacity of sustainable energy production, address issues of overproduction, and provide remote areas with green power that was previously out of reach.

Electrolysis is a chemical process in which water (H2O) is split into hydrogen gas (H2) and oxygen gas (O2) using electrical current. This process takes place in an electrolysis cell, where water is immersed, and two electrodes, usually made of platinum or other catalytic materials, are installed.

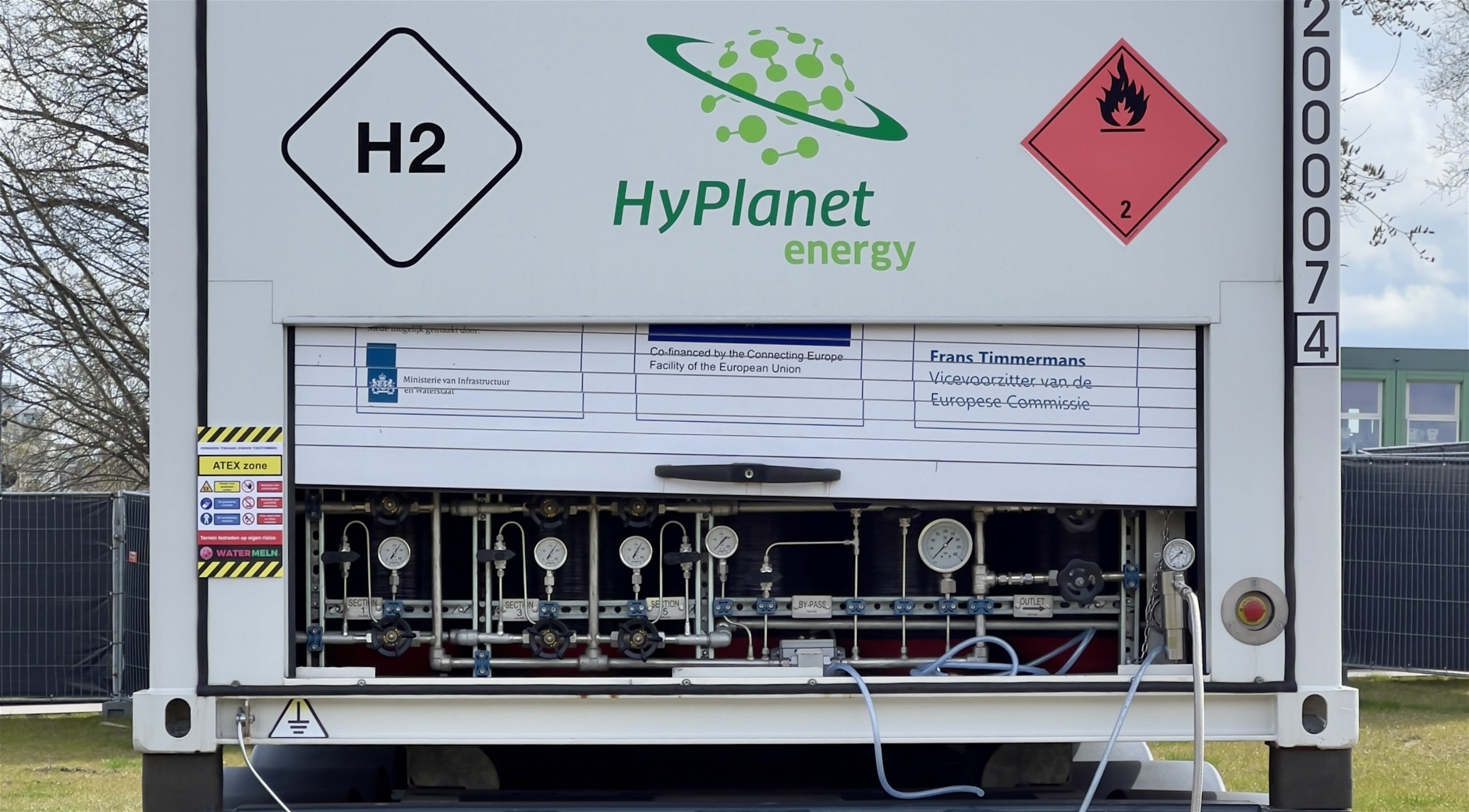

After production through electrolysis, hydrogen needs to be stored for future use. A common method for hydrogen storage is at high pressure. Compressed hydrogen gas is stored in special tanks designed to withstand high pressure. Pressure levels typically range from 350 to 700 bar (5,000 to 10,000 psi), depending on the specific application. In our case, we use tanks with 300 or 500 bar.

The stored hydrogen gas can be transported to locations where it is needed, such as construction sites or festivals. Upon use, the hydrogen gas is released from the tanks, distributed, and converted into electricity and heat by our fuel cell system.

After filling out the form, the Watermeln team will get in touch as soon as possible.

Find frequently asked questions about Watermeln and our products

Where can I find the terms and conditions?

The general terms and conditions can be accessed via this link, and they are also registered with the Chamber of Commerce; Watermeln B.V.

Is Watermeln's solution more expensive than a (hybrid) diesel generator?

It depends on the project, the duration, the energy demand, and the market price for hydrogen. Generally, the more energy is consumed, the smaller the price difference. This is because our system is more efficient, resulting in lower costs per kWh. Due to the novelty of fuel cell technology, the rental price is currently higher. When you combine both costs into a total cost of operations (TCOP), in most cases, we can compete with hybrid diesel generators.

How does Watermeln’s pricing model work?

Energy itself is already complex enough, we therefore simplified our pricing model

It’s based on two components

The service tariff includes: rent, installation, transport, and online monitoring (incl. user access)

The usage tariff includes: hydrogen gas, and transport

What is not included?

Does the Watermeln unit meet the required certification and standards?

The Watermeln unit is CE approved by an independent party and thereby meets the corresponding standards (ISO and NEN). It also complies with European ATEX directives and has an explosive safety survey and documentation.

Does the safety requirements for diesel generators also apply for hydrogen fuel cell generators

Other than a Diesel genset, the Watermeln 200 unit is working according to a chemical reaction, instead of a combustion oxidation reaction. Therefore, current Dutch regulatory aspects for “Stookinstallaties'' do not apply for the Watermeln installation.

The activities are of a temporary nature and are therefore not considered as “inrichting”. This means that it does not fall under the Besluit Activiteiten Leefomgeving (BAL) en Besluit Omgevingsrecht (BOR).

The supply and installation of the H2 gas cylinders must comply with the PGS 15 guidelines. As long as the total hydrogen gas bottle system contains <1 ton H2 and remains directly connected to the system, these activities are not subject to a permit requirement. However, an official notification (notification requirement) > 4 weeks prior to the hydrogen activities to the competent authority is required. Certain local regulations may possibly apply. We therefore recommend notification and discussion with local environmental and safety authorities.

Which safety measures should I comply with?

The overall system follows the guidelines of PGS 15 and ATEX, which include:

Watermeln: 470 kg per m2

Specific safety requirements are tied to location, accessibility and project description. Watermeln can guide you through this process.

Is hydrogen sustainable

The carbon footprint of hydrogen depends on its source. While hydrogen is free of harmful emissions at the point of use, carbon can be released to the atmosphere during its production. There are numerous ways to produce hydrogen, but let’s focus for the purpose of the question on the three main types of hydrogen production techniques:

Green hydrogen is produced by electrolysis of water (dividing H2O, into H2; hydrogen, and 02; oxygen) using only electricity from renewable sources, it can therefore be considered “zero-carbon hydrogen”

Blue hydrogen is produced from natural gas via a process called steam reforming, and the residual CO2 is captured via some form of carbon capture and storage (CCS), and can be considered “low-carbon”

Gray hydrogen produced from natural gas without carbon capture and storage (CSS), and can be considered “with-carbon”

Most of the existing users of hydrogen (mainly industrial companies) are using gray hydrogen, as this is the most common form of hydrogen. Due to decreasing costs of renewable energy and equipment, and tighter regulations, the amount of produced green hydrogen is increasing fast.

What type of hydrogen is Watermeln using?

Watermeln is only using high quality (5.0) green certified hydrogen made from electrolysis that’s directly connected to a renewable energy source, or PPA wind and solar contract.

Do I need to arrange the hydrogen myself?

No, this is not necessary. Watermeln has long-term agreements with producers, and will supply and install the required hydrogen.

How does Watermeln’s fuel cell work?

Fuel cells work like batteries, both work with a chemical reaction, but fuel cells do not run down or need recharging. They produce electricity and heat as long as fuel is supplied. A fuel cell consists of two electrodes—a negative electrode (or anode) and a positive electrode (or cathode)—sandwiched around an electrolyte. A fuel, such as hydrogen, is fed to the anode, and air is fed to the cathode. In a hydrogen fuel cell, a catalyst at the anode separates hydrogen molecules into protons and electrons, which take different paths to the cathode. The electrons go through an external circuit, creating a flow of electricity. The protons migrate through the electrolyte to the cathode, where they unite with oxygen and the electrons to produce water and heat [1].

There are different types of fuel cells, each with its own characteristics. Watermeln is using a PEM fuel cell.

Source:

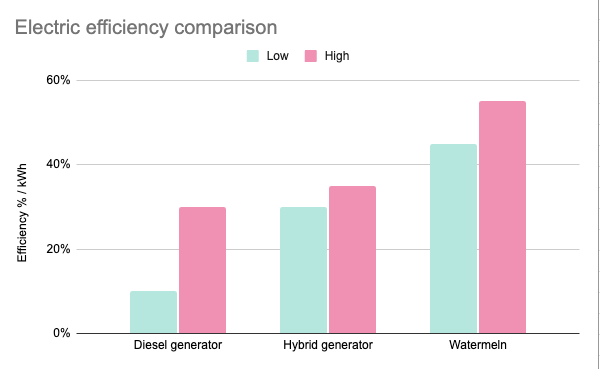

How does the electrical efficiency of Watermeln’s system compare to conventional diesel generators and hybrid systems?

The graph below shows the average efficiency of a Stage 5 diesel generator and a hybrid system (stage 5 diesel generator and li-ion battery). By applying a battery to a diesel generator, large fuel savings can be realized, and therefore lower the CO2 impact. However, combustion as a electricity production method, will never meet the same high efficiency standards with a chemical reaction like a fuel cell, therefore Watermeln’s system typically delivers up to 4 times higher efficiency than conventional combustion engines.

Sources:

Graph: electrical efficiency comparison between Diesel [1] / hybrid generators [2] and Watermeln system

How much CO2 savings can be realized with a Watermeln system?

We have set-out a comparison from “Well to Power”(WtP) for 4 variants in the table below (Diesel, Hybrid, Gray Hydrogen and Green Hydrogen). Well to Power (WtP) means that we have considered the CO2 emissions emitted throughout the complete value chain (resources, production, transport, and consumption).

Watermeln uses only green hydrogen, therefore we realize a 96% CO2 reduction on average compared to a diesel generator (WtP).

Diesel | Hybrid | Grey hydrogen fuel cell | Green hydrogen fuel cell | |

CO2e to Produce and Transport (kg of fuel) | 0,95[1] | 0,95[1] | 12,5 [1] | 1,14 [1] |

CO2e at the point of use (kg) | 2,6[1] | 2,6[1] | 0[1] | 0[1] |

Total CO2e (kg) (WtP) | 3,55 | 3,55 | 12,5 | 1,14 |

Energy per kg of fuel (kWh LHV) | 11,8[2] | 11,8[2] | 33,3[2] | 33,3[2] |

Typical generator efficiency (low/high) | 10% – 30% | 25% – | 45% – 55% | 45% – 55% |

Useful energy produced (kWh) | 1,18 – 3,54 | 2,95 – | 15,0 – 18,31 | 15.0 – 18,31 |

CO2 emissions on useful energy ratio (kg/kWh) (L/H) | 3,01 – 1,00 | 1,20 – 0,86 | 0,83 – 0.68 | 0,07 – 0,06 |

CO2e reduction compared with diesel (L/H) | n/a | 42% | 53% (range: 32% – 72% **) | 96% (range: 94% – 98% **) |

Table 1: Well to power CO2 emission comparison between 4 solutions

Sources:

1 https://www.co2emissiefactoren.nl/lijst-emissiefactoren/

2. https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html

Is HVO diesel a good alternative

Hydrotreated Vegetable Oil (HVO) can function as a diesel replacement. There are various mixtures HVO 20 (meaning 20% HVO mixed with fossil diesel) and HVO 100 (being 100% HVO diesel). Due to the carbon absorption nature of plants, HVO can technically realize up to 85% CO2 reduction [1] from Well to Power (from production to usage).

There is currently much debate around reduction claims as, depending on the feedstock and the supply chain, the production of HVO can lead directly or indirectly to deforestation (e.g. palm oil is often used as a resource [2]), which has significant environmental, ecological and CO2 implications. Also, unlike hydrogen used in fuel cells, HVO still is used in combustion applications that are 4 times less efficient, and are emitting large amounts of CO2, NOx and other pollutants at the point of use (tail-pipe emissions). Causing a significant amount of local pollution - contributing to global warming, and major health issues for humans[3].

Therefore, we can conclude that HVO is a short term solution on minimizing conventional diesel, however it is not a sustainable replacement, or equal solution to renewable energy.

Sources:

1 https://www.co2emissiefactoren.nl/lijst-emissiefactoren/

2 https://biofuels-news.com/news/palm-oil-dominated-biofuel-feedstock-in-2021-quota-year/

3 https://www.eea.europa.eu/publications/air-quality-in-europe-2022

What is the difference between batteries and fuel cell hydrogen generators?

Batteries (most commonly Li-ion batteries) and fuel cell hydrogen generators are not the same thing. Both use a chemical reaction to release energy in the form of electricity, however batteries are meant to store and quickly charge or discharge electricity - and fuel cell hydrogen generators are designed to produce electricity from hydrogen gas.

For a fuel cell system, storage and power are separated, by use of a hydrogen gas tank (often compressed to up to 500 bar) and the fuel cell to release electrical energy from the hydrogen gas.

Battery technology is a great way to provide electricity for short term use cases that require high power, and limited energy capacity. But for a battery to be usable, it must be recharged. Therefore, it is often combined with a (small) grid connection.

For off-grid applications where high energy output and capacity is required, a battery solution with enough capacity will prove too bulky and expensive, and would also need to be transported off site to be recharged (even several times a day). The long charging time between uses also means batteries are not practical for assets that are highly utilized. So while batteries can be useful for providing additional peak power for grid connected use cases, or short term projects with low energy capacity needs, hydrogen is much better suited for use cases where diesel has traditionally been employed – off grid, high-power & energy consumption, long to medium term applications.

To simplify we have made a pro and con comparison between both technologies

Batteries (Li-ion) | Hydrogen fuel cell generator | |

Pro |

|

|

Con |

|

|

Table 2: comparison between battery and hydrogen fuel cell generator technologies

As you can see, both technologies are complementary to each other, and both play an important role in the transition to renewable energy usage and storage. Therefore, Watermeln combines the best of both technologies into its system. By adding a battery we can deliver instant power, higher efficiencies and seamless refueling when the hydrogen is decoupled.

We can't find the internet

Attempting to reconnect

Something went wrong!

Hang in there while we get back on track